How Are Concrete Block Interior Walls Finished?

When building or remodeling homes with concrete block interior walls in basements, or other areas of their homes, homeowners are sometimes left with interior walls of exposed concrete blocks.

Published: by SEMCO FL

How Are Concrete Block Interior Walls Finished?

When building or remodeling homes with concrete block interior walls in basements, or other areas of their homes, homeowners are sometimes left with interior walls of exposed concrete blocks. One of the reasons the walls might not be finished yet is because you’ve recently been installing all the plumbing and electrical workings, and so finishing the wall is obviously not possible until all that is done — otherwise you’d have to break into it and destroy all your hard work! There are 3 main ways that people generally use to finish these concrete walls: painting, pargeting, and wood paneling/drywall, all of which we will describe below. Some may believe that these are the only 3 viable options, but that isn’t the case. In today’s blog, we want to explain how a system like Semco can be used as a faster, more efficient, and more convenient way to finish concrete block interior walls.Finishing Concrete Block Interior Walls: Painting

Painting is the simplest method of finishing a concrete block interior wall. It’s ideal for those who perhaps aren’t worried about the exposed concrete itself or the visible joints between each block, but perhaps just don’t like the drab color. Painting simply applies a nice colorful coat to the concrete. In a small space like the basement, light and bright colors can help lend a sense of space to the room. The only slightly complex step required in the painting process is priming, for which it’s best to use a water-based latex primer, followed by your finishing paint. Once the wall is primed and ready, you can treat it like a blank canvas.

Finishing Concrete Block Interior Walls: Wood Paneling Or Drywall

Finally, another common practice for finishing concrete block interior walls is placing wood paneling on the walls to create a solid (and hopefully stylish) covering for the concrete blocks and their unsightly joints. Paneling is installed by first attaching horizontal furring strips to the wall with a hammer drill and screws, and then placing tongue and groove pine boards vertically against them. If you don’t want to use pine boards, you could use something a bit more budget-friendly like drywall. If you use drywall you will have to tape and mud the joints and then apply a coat of paint which adds substantially to labor and material costs. Once the wood is all in place, you can then treat it with linseed oil or similar wood oil to provide protection.A Better Way To Finish Concrete Block Interior Walls: Semco

These ways are tried-and-tested, but they seem to come with the same underlying caveat: the more you want to cover and finish a concrete block interior wall, the more materials you need to invest in and the more physical labor needs to be done. Semco is a product that breaks this rule, offering a very simple way to retain a stylish, textured concrete finish and the benefits that come from that, but also removing any semblance of unsightly block joints.

How Does Semco Work? Concrete Block Interior Walls

The Semco system is a kind of micro-topping that can be placed over virtually any substrate – including your concrete wall. Once the wall is primed and ready, you can simply trowel on the Semco in layers and then leave it to cure. Once it does, it creates a non-porous, hard concrete-like outer protective shell that simultaneously hides the wall joints and creates a pleasing finish.

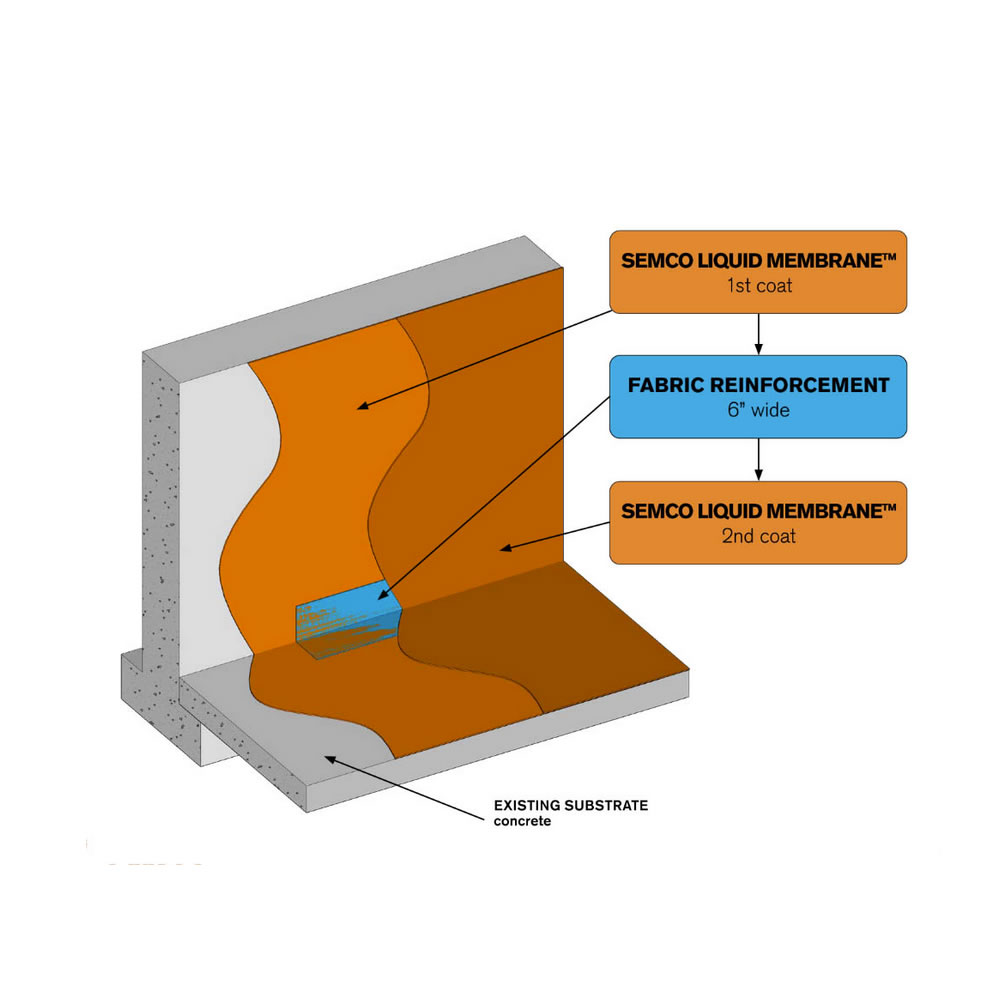

If you’re applying Semco in a basement where you have real concerns about water intrusion, then you can double up on Semco’s natural non-porous state by applying the Semco Liquid Membrane full waterproofing solution. It’s actually a far superior solution for basements, where keeping moisture out is an absolute necessity. Plus, if you get a flood in your basement the Semco system will be unaffected unlike with paint, drywall, or paneling.

Benefits Of Semco

1. Semco is a Vapor Barrier Even without additional waterproofing, Semco provides a non-porous vapor barrier that prevents moisture from getting into your concrete. Where concrete is naturally porous and thus needs to be sealed, Semco creates a protective barrier that will actively protect against any moisture intrusion. At the same time, it provides physical protection for the wall beneath, even though it’s only ⅛ of an inch thick as a layer on the surface of your concrete block wall. 2. It Can be Further Waterproofed As we mentioned above, when you need to maximize protection against water, as you might in a basement, for example, then Semco’s natural protection can be augmented with Semco’s own Liquid Membrane which goes beneath the micro cement layers. The level of protection is such that you could turn your basement into a giant bathtub if you really wanted! 3. It Has an Integral Color and Finish Finally, once Semco is applied, it adds its own integral color and finishes to the wall so you needn’t take any further action if you don’t want to. This finish is used in the homes of movie directors, fashion designers, athletes, and more. If you did want to paint on top of Semco, you can easily paint the surface and color without losing any of Semco’s inherent benefits. Semco can be pigmented in any color in either solid or variegated colors. The Semco will still be as durable as ever.

Let’s hear from you!

Ready to take it a step further? Let’s start talking about your project or idea and find out how we can help you.

Have questions? We can help!

Have Any Questions?

We would love to hear from you! Let’s start talking about your project or idea and find out how we can help you.

- Call us: 954-852-7281

- Get a quote: Free Quote

Since 1991

Concrete & Tile Resurfacing Solutions

SEMCO Florida, Innovation driven surface engineering company that specializes in developing surfacing products for floors, walls, pool decks and waterproofing.