Concrete Spalling: How to Identify and Fix

Do you have a concrete surface that is flaking and chipping like old paint? This is commonly known as spalling concrete.

Published: by SEMCO FL

Spalling concrete is a result of chemical and physical processes.

Do you have a concrete surface that is flaking and chipping like old paint? This is commonly known as spalling concrete and it is a source of great irritation to homeowners, businesses, builders and city municipalities. Here we go over in detail what spalling concrete is and how you can go about fixing it and restoring your concrete surface to a presentable state.

What Is Spalling Concrete?

Before understanding what concrete spalling is, it is helpful to understanding what a spall is. A spall is defined as flakes or chips of surface material that have come off a larger solid body. Spalling can happen to almost any artificial surface, and concrete is certainly not exempt.

The symptoms of spalling concrete are the flaking, chipping and large chunks that you see missing from your concrete surface, exposing the coarse, rocky concrete aggregate. Those are the symptoms, but spalling concrete is a little more complex than just surface level appearance. This form of spalling is the result of chemical and physical process that are happening within the concrete itself. It is a relatively common problem with a number of causes varying from how the concrete was mixed to environmental conditions.

What Causes Spalling In Concrete?

Here is a brief list of the things that can cause spalling.

- Corrosion of reinforcing bar. Water that permeates an unsealed concrete surface can causes the corrosion of the rebar. The rust from the rebar occupies more space than the original rebar, causing an internal pressure buildup and consequently, a spall.

- Freeze and thaw cycle. This is a very common problem in northern states, in which water that has penetrated to concrete freezes, expands, puts internal pressure on the concrete, and over enough cycles causes it to spall. There is a strong force exerted on the top layer and it can cause parts of it to slake off.

- An alkali silica reaction. This type of reaction results from a reaction that occurs between the reactive silica found within the concrete structure such as aggregates and the alkaline cement pastes. This reaction causes increased pressure in the concrete, swelling and ultimately results in spalling concrete.

Can Spalling Be Prevented?

As we have seen, most spalling occurs as a result of moisture getting into the concrete and either causing corrosion or swelling. In other cases, spalling occurs as a result of poor concrete mixing methods. This is much less common. The most effective way to prevent the spalling of concrete is to use a concrete waterproof sealant to stop water from getting in where it can cause damage. Product’s such as SEMCOFL’s Sealers which are both penetrating and topical prevent moisture from getting in the concrete while preventing staining and increasing hardness.

Can Spalling Be Repaired?

If your concrete has already succumbed to spalling, don’t worry, you can repair it. The type of repair and the work involved depends on where the concrete spall is located, how deep it is, whether is is on a vertical or horizontal surface and if there is any exposed rebar. It is critical to remove all of the loose material through abrasion or other mechanical means. Once you have gotten rid of the loose and soft material. A product such as Semco’s Xbond Stone can be used to restore the original shape and size.

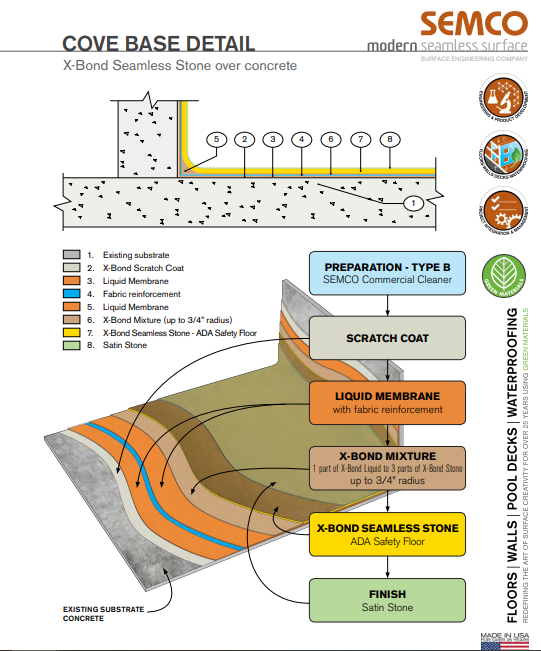

The installation steps include the following:

- Remove all loose material and dust to maximize the bond

- Roll Semco’s Xbond Liquid primer without letting it dryCreate a scratch coat by applying 1:2 Xbond Liquid:Xbond Stone and apply with a concrete broom

- Brown Coat: If more than a 1/4″ of thickness must be achieved to restore the concrete then use 1:1:3 coat of 1 part Xbond liquid:1 part Xbond brown Coat Additive: 3 parts Xbond Stone to create the desired shape

- Finish the Brown Coat with a final coat of 1:2.5 – 1 part Xbond Liquid:2.5 parts Xbond Stone to smooth and create a final finish

- Apply desired sealer such as Semco’s Satin Stone or Semco’s Natural Shield.

Concrete Wall Spalling Repair

If you have spalling in a basement wall or other vertical concrete surface, the fix can be a little involved. To fix a concrete wall that is spalling, you first need to cut into the concrete around the spalled area. Make the cut about three-eighths of an inch deep with a circular saw.

Next, use a hammer and chisel to remove the concrete from the cut area. This step should expose the reinforced steel bars.

Break away any concrete attached to the rebar.

The rebar will likely be rusted. Remove any rust with a wire brush until you reveal an unrusted surface. To prevent further corrosion and spalling, paint the bars with an anti-rust paint.

The final step is to add the new concrete. Make sure to pack the concrete well into the hole so that no gaps appear which could weaken the wall.

Repair Spalling Concrete On A Horizontal Surface

Spalling concrete on a horizontal surface like a driveway or sidewalk is not only an aesthetic problem, it is a safety hazard. Spalling on a concrete driveway or sidewalk may require a more comprehensive solution to ensure that it does not return. The most common method for repairing spalling in horizontal surfaces is to resurface and seal the surface with a resurfacing solution. The advantage of using this method is that it not only repairs the spalling concrete, but prevents spalling issues from returning.

How Do You Fix Spalling Concrete On Driveways And Sidewalks?

Some people mistakenly believe that you need to completely remove the old concrete and repour new concrete to fix and prevent spalling on driveways or sidewalks. Fortunately, repairing spalled concrete is often much easier and cheaper than that.

It is usually fixed with a cement and concrete resurfacing overlay. A good concrete resurfacing product like Semco’s Xbond can fill in cracks, repair gaps and resurface the concrete without having to remove it. To prevent water penetration into concrete a great penetrating sealer is made by RexPro (rexprosealers.com). After the concrete is resurfaced, to prevent further spalling it is recommended that a waterproof concrete sealing system is used.

Repair Concrete Spalling By Resurfacing

Concrete resurfacing is used to repair and revitalize concrete surfaces suffering from stuff as minor as stains and light corrosion due to the elements, to more structural issues like spalling.

Spalling can be patchy or can cover the entire extent of the surface. In cases of isolated spalling, a localized patching solution might be suitable. In cases where the spalling is more extensive, you may want to consider a resurfacing solution. Concrete resurfacing systems are designed to cover cracks, spalling and other imperfections with a durable mechanically bonded microcement. The concrete resurfacing product is then sealed to ensure that you do not have a repeat of the spalling. What is great about this option too is that you can incorporate decorative finishes depending on your beautifying goals.

Have questions? We can help!

Have Any Questions?

We would love to hear from you! Let’s start talking about your project or idea and find out how we can help you.

- Call us: 954-852-7281

- Get a quote: Free Quote

Since 1991

Concrete & Tile Resurfacing Solutions

SEMCO Florida, Innovation driven surface engineering company that specializes in developing surfacing products for floors, walls, pool decks and waterproofing.